When Marie Dubois flicks on the lights in her Lille apartment each morning, she probably doesn’t think about the paper-thin metal sheets that make it all possible. But deep inside every transformer humming quietly in her neighborhood, ultra-precise electrical steel is doing the invisible work of keeping Europe’s power grid running smoothly.

Now, that same specialized steel is becoming the foundation of something much bigger. As electric cars multiply on French roads and wind turbines sprout across the countryside, the demand for these seemingly mundane metal sheets is exploding into what experts predict will be a €57 billion global market by 2032.

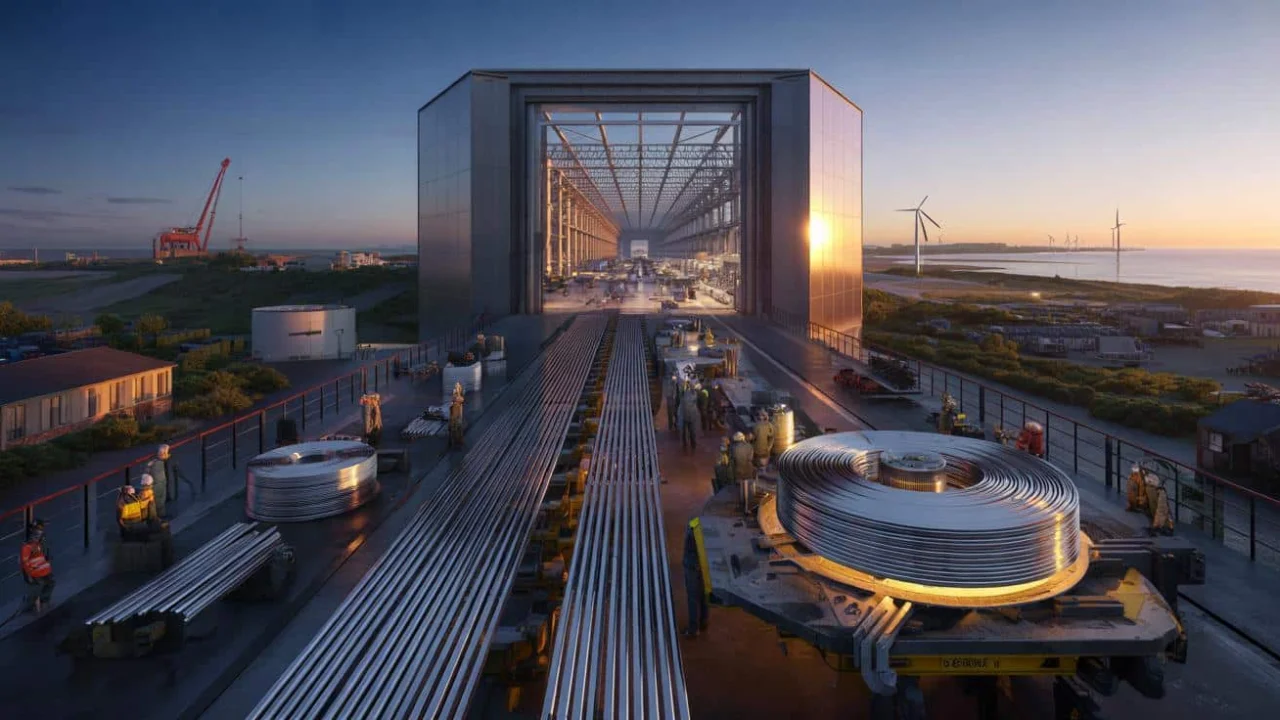

That’s why ArcelorMittal is betting big on a massive industrial transformation just outside Dunkirk, where half a billion euros is being poured into retooling a traditional steel plant for the electrical steel market of tomorrow.

The €500 Million Gamble That Could Transform European Energy

At the Mardyck facility near Dunkirk, something remarkable is happening. ArcelorMittal, the steel giant that once dominated global production, is making its largest European investment in a decade – a €500 million commitment to electrical steel production.

- This 5 cylinder engine hits 16,000 rpm and might be Europe’s secret weapon against electric cars

- This February polar vortex disruption broke 70-year records while politicians insist climate emergency isn’t real

- Your body keeps ringing a quiet alarm that most people never recognize — here’s what feeling on edge really means

- Why kitchen wall units are vanishing from modern homes (and what’s replacing them)

- This Japanese egg frying technique lets you cook perfect eggs with almost no oil at all

- Homeowners discover toilet bowl cleaning trick that makes professional cleaners look like frauds

This isn’t just another industrial upgrade. The facility represents a fundamental shift from producing regular steel for cars and buildings to manufacturing the specialized materials that form the magnetic heart of every electric motor, transformer, and generator powering Europe’s energy transition.

“We’re essentially rewiring our entire production philosophy,” explains a senior plant manager familiar with the project. “Where we once measured success in tons of basic steel, we now focus on the magnetic properties of sheets thinner than human hair.”

The timeline is ambitious but clear. Three new production lines dedicated exclusively to electrical steel will come online by the end of 2025, expanding to five lines by 2027. Each line represents cutting-edge technology designed to meet the exacting standards of the rapidly growing electrical steel market.

Inside the Numbers: Why This Market Matters So Much

The electrical steel market isn’t just growing – it’s experiencing unprecedented expansion driven by global electrification trends. Here’s what the data reveals about this specialized industry:

| Market Segment | 2023 Value | 2032 Projection | Growth Driver |

|---|---|---|---|

| Global Electrical Steel | €28 billion | €57 billion | Electric vehicle motors |

| European Market Share | 22% | 25% (projected) | Renewable energy infrastructure |

| Wind Turbine Demand | 15% | 28% (projected) | Green energy transition |

The key applications driving this growth include:

- Electric vehicle motors requiring high-efficiency magnetic cores

- Wind turbine generators demanding lightweight, durable materials

- Power grid transformers needing enhanced energy efficiency

- Industrial motor systems upgrading for sustainability

- Renewable energy storage systems requiring specialized components

“The numbers tell a compelling story,” notes an industry analyst tracking European steel markets. “Every electric car needs about 80 kilograms of electrical steel, while a single large wind turbine requires nearly 600 kilograms. Multiply that across millions of vehicles and thousands of turbines, and you see why this market is exploding.”

What Makes Electrical Steel So Special

Unlike the heavy beams most people picture when they hear “steel,” electrical steel is a precision-engineered material that looks deceptively simple. These ultra-thin strips, often just 0.27 millimeters thick, are specially treated with silicon to optimize their magnetic properties.

The manufacturing process is incredibly complex. The steel must be rolled to exact specifications, heat-treated at precise temperatures, and coated with insulating layers thinner than a soap bubble. Even tiny impurities can ruin the magnetic efficiency that makes these materials valuable.

ArcelorMittal’s Mardyck investment focuses on grain-oriented electrical steel, the premium grade used in power transformers and large generators. This type requires even more sophisticated production techniques, including controlled cooling processes that align the steel’s crystal structure for optimal magnetic performance.

“Think of it like tuning a violin,” explains a metallurgical engineer working on the project. “Every aspect of the steel’s internal structure must harmonize perfectly to achieve the magnetic properties our customers demand.”

Real-World Impact: Who Benefits and How

The ripple effects of expanding electrical steel production extend far beyond the factory gates in Dunkirk. Across Europe, industries are watching this development closely because it addresses a critical supply chain vulnerability.

Currently, China dominates global electrical steel production, controlling roughly 70% of the market. European manufacturers of electric motors, transformers, and renewable energy equipment have grown increasingly concerned about supply security, especially as geopolitical tensions rise.

Automotive companies are particularly interested. Major European carmakers like Stellantis, BMW, and Volkswagen are investing billions in electric vehicle production, but they need reliable sources of high-quality electrical steel for their motor manufacturing.

The renewable energy sector faces similar challenges. Wind turbine manufacturers like Vestas and Siemens Gamesa require steady supplies of electrical steel for their growing order books. Every new offshore wind farm represents hundreds of tons of electrical steel demand.

Even ordinary consumers will feel the impact. More efficient transformers using advanced electrical steel can reduce energy losses in power grids by up to 30%. That translates directly into lower electricity bills and reduced carbon emissions from power generation.

“This investment isn’t just about steel production,” emphasizes a European energy policy expert. “It’s about energy security, industrial competitiveness, and climate goals all wrapped into one strategic move.”

Challenges and Competition in a Changing Market

Despite the promising outlook, ArcelorMittal faces significant challenges in capturing its share of the growing electrical steel market. Chinese producers have years of experience and massive scale advantages that won’t disappear overnight.

Quality standards in the electrical steel market are unforgiving. Customers test every batch for magnetic properties, energy losses, and mechanical strength. A single production error can result in rejected shipments worth millions of euros.

The company is also competing against established European players like thyssenkrupp in Germany and Aperam, while Japanese giants like Nippon Steel continue to set technology benchmarks globally.

Labor costs present another hurdle. The Mardyck facility will employ hundreds of highly skilled workers who command premium wages compared to production centers in Asia. ArcelorMittal is betting that proximity to customers and superior product quality will justify the cost difference.

“We’re not trying to compete on price alone,” admits a company executive involved in the project planning. “Our strategy focuses on technical excellence, delivery reliability, and the kind of customer service you can only provide when your factory is a few hours’ drive from your biggest clients.”

The Bigger Picture: Europe’s Industrial Strategy

The Mardyck investment reflects broader European Union priorities around strategic autonomy and industrial resilience. Brussels has identified electrical steel as a critical material for the green transition, similar to battery minerals and semiconductor chips.

French government support for the project includes favorable financing terms and regulatory fast-tracking. The facility aligns perfectly with France’s broader industrial strategy of maintaining manufacturing leadership in advanced materials.

Regional economic development is another factor. The Hauts-de-France region has worked hard to attract high-tech manufacturing investments, positioning itself as a hub for industries supporting energy transition. The ArcelorMittal expansion fits naturally into this vision.

Success at Mardyck could inspire similar investments across Europe, potentially reshaping global electrical steel market dynamics over the next decade. Industry observers are watching closely to see whether European producers can effectively challenge Asian dominance in this critical sector.

FAQs

What exactly is electrical steel and why is it important?

Electrical steel is a specialized silicon-enhanced steel designed for magnetic applications in motors, transformers, and generators. It’s crucial for electric vehicles, renewable energy equipment, and power grid infrastructure.

How big is the electrical steel market expected to become?

The global electrical steel market is projected to reach €57 billion by 2032, growing from approximately €28 billion today, driven primarily by electric vehicle adoption and renewable energy expansion.

Why is ArcelorMittal investing €500 million in this facility?

The company sees electrical steel as a high-value growth market with less competition than traditional steel products. The investment helps reduce European dependence on Asian suppliers while positioning ArcelorMittal closer to key customers.

When will the new production lines be operational?

Three new electrical steel production lines are scheduled to begin operating by the end of 2025, with two additional lines coming online in 2027.

How does this investment affect European energy security?

By producing electrical steel locally, European manufacturers of electric motors, transformers, and renewable energy equipment reduce their dependence on Chinese suppliers, improving supply chain resilience.

What makes electrical steel different from regular steel?

Electrical steel contains silicon additives and undergoes special processing to optimize magnetic properties while minimizing energy losses. It’s much thinner than regular steel and requires precise manufacturing techniques.