Sarah Martinez never thought much about nuclear waste until her teenage daughter asked a simple question during dinner: “Mom, what happens to all that radioactive stuff when the power plants are done with it?” Sarah, an engineer at a renewable energy company, realized she didn’t have a good answer. Like most people, she knew it got buried somewhere for thousands of years, costing billions and solving nothing.

That conversation happened two years ago. Today, Sarah works for a Colorado startup that’s turning that “useless” waste into something fusion reactors desperately need. The irony isn’t lost on her – the material everyone fears most might be the key to unlimited clean energy.

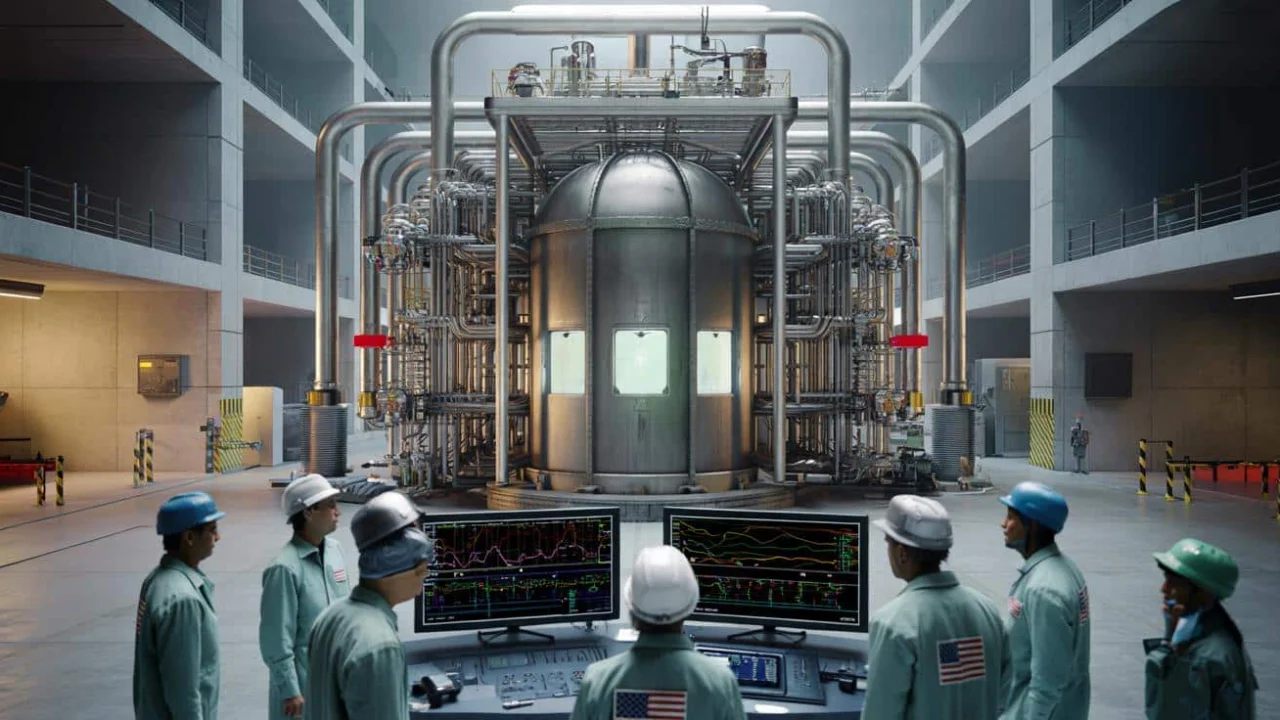

Welcome to the strange world of tritium production from nuclear waste, where America’s boldest scientists are betting they can solve two massive problems with one elegant solution.

When Trash Becomes Treasure: The Tritium Revolution

Here’s what’s happening in labs across America right now. Engineers are taking spent nuclear fuel – the radioactive waste that utilities pay billions to store – and transforming it into tritium, the rarest fuel on Earth.

- This tiny kitchen herb clears indoor odours in minutes and keeps rooms fresh for hours without chemicals

- Orca attacks on boats spark fierce debate as authorities face impossible choice between wildlife and sailors

- When excessive politeness becomes a psychological red flag that experts say you shouldn’t ignore

- Marine authorities consider stunning or killing orcas after yacht attacks spark unprecedented debate

- Rats ate London’s internet cables and killed a £300 million rescue deal

- The shocking truth about brassica oleracea varieties that grocery stores don’t want you to know

Tritium is hydrogen’s radioactive cousin, and it’s absolutely essential for fusion reactions. Without tritium, fusion reactors can’t work. The problem? Natural tritium is incredibly rare, and the world’s supply is running out fast.

“We’re essentially mining stars from garbage,” explains Dr. James Chen, a nuclear physicist working on waste-to-tritium conversion. “The same isotopes that make waste dangerous for millennia can be converted into the fuel that could power civilization cleanly forever.”

The process sounds like science fiction, but it’s surprisingly straightforward. Scientists bombard nuclear waste with carefully controlled neutron beams. Some of the long-lived radioactive elements get nudged into becoming tritium instead of just sitting there being dangerous for 100,000 years.

American companies and national laboratories are racing to perfect this technology. The potential payoff is enormous – solve the nuclear waste crisis while creating the most valuable substance in the energy world.

The Numbers Behind the Nuclear Gold Rush

Let’s break down why tritium production from waste is creating such excitement in both the nuclear and fusion industries:

| Current Situation | Waste-to-Tritium Solution |

|---|---|

| Global tritium supply: 20kg annually | Potential production: 50+ kg annually |

| Price per gram: $30,000 | Production cost: Under $15,000 per gram |

| Current sources: Canadian reactors | New sources: U.S. waste stockpiles |

| Waste storage cost: $96 billion over 100 years | Waste processing: Revenue-generating |

The key advantages of this approach include:

- Abundant raw material: America has over 80,000 tons of nuclear waste sitting in storage

- Dual problem solving: Reduces waste volume while creating valuable tritium

- Economic transformation: Turns a costly liability into a profitable resource

- Energy independence: Reduces reliance on foreign tritium sources

- Fusion enablement: Provides the fuel needed for commercial fusion power

Several American companies are already operating pilot programs. One Colorado facility processes small batches of reactor waste in shipping-container-sized units. The tritium output is measured in grams per year, but even that small amount is worth hundreds of thousands of dollars.

“Every gram we produce is one gram closer to making fusion commercially viable,” says Maria Rodriguez, CEO of a waste-processing startup. “The fusion industry is literally waiting for us to scale up.”

What This Means for Energy’s Future

The implications extend far beyond just solving two technical problems. This technology could fundamentally reshape how we think about nuclear energy, waste management, and the path to fusion power.

For fusion companies, reliable tritium production removes their biggest bottleneck. Most private fusion ventures have impressive reactor designs but struggle with fuel supply. Domestic tritium production could accelerate commercial fusion by decades.

For nuclear utilities, waste becomes an asset instead of a liability. Plants that currently pay enormous fees for long-term storage could instead sell their waste to tritium producers. The economics of nuclear power improve dramatically when waste generates revenue.

The environmental impact is equally significant. Instead of burying radioactive materials for millennia, we’re actively reducing their radioactive lifespan while creating clean energy fuel. It’s nuclear recycling at its most elegant.

“This changes the entire nuclear conversation,” explains Dr. Lisa Park, a energy policy researcher. “Suddenly, we’re not talking about waste disposal costs – we’re talking about waste as a strategic resource.”

The geopolitical implications are substantial too. Countries with large nuclear waste stockpiles – like the United States – suddenly possess the raw materials for fusion fuel independence. This could reshape global energy dynamics as fusion technology matures.

The Race Is On: Who’s Leading the Charge

Multiple American entities are competing to perfect waste-to-tritium technology. National laboratories like Oak Ridge and Los Alamos are developing the fundamental science, while private companies focus on scaling up production.

The competition is intense because the market opportunity is enormous. Fusion companies need reliable tritium supplies to attract investment and begin commercial operations. The first organization to provide large-scale tritium production will essentially enable the entire fusion industry.

Some facilities are already processing waste in small quantities, learning how to optimize conversion rates and manage safety protocols. Others are designing larger systems capable of handling tons of waste annually.

“We’re not just building tritium production facilities,” notes Tom Wilson, a former nuclear plant manager now working in waste conversion. “We’re building the infrastructure that will make fusion power a reality.”

The timeline is aggressive but achievable. Several projects expect to demonstrate large-scale tritium production within five years. If successful, commercial fusion reactors could have reliable fuel supplies by the early 2030s.

That would represent one of the fastest technological transformations in energy history – from nuclear waste problem to fusion fuel solution in less than a decade.

FAQs

What exactly is tritium and why is it so valuable?

Tritium is a radioactive form of hydrogen that’s essential for fusion reactions. It’s extremely rare naturally and currently costs about $30,000 per gram, making it more valuable than diamonds.

Is it safe to convert nuclear waste into tritium?

The conversion process happens in highly controlled environments with extensive safety systems. The resulting tritium is actually easier to handle safely than the original nuclear waste.

How much tritium can be produced from existing nuclear waste?

Current estimates suggest American nuclear waste could potentially produce 50+ kilograms of tritium annually, more than doubling the global supply.

When will this technology be available commercially?

Several facilities are already operating at pilot scale. Large-scale commercial production could begin within 5-7 years if current development continues.

Could this solve both the nuclear waste problem and fusion fuel shortage?

Potentially yes. While it won’t eliminate all nuclear waste, it could significantly reduce waste volumes while providing the tritium needed for commercial fusion power.

Who’s investing in this technology?

Both government labs and private companies are developing waste-to-tritium systems. Fusion companies are particularly interested as they need reliable tritium supplies to operate.